|

QINGDAO AORUI PLASTICS MACHINERY CO., LTD.

|

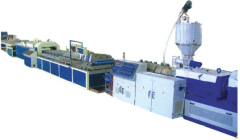

building/construction formwork Production machine

| Payment Terms: | T/T,L/C |

| Place of Origin: | Shandong, China (Mainland) |

|

|

|

| Add to My Favorites | |

| HiSupplier Escrow |

Product Detail

PE plastic construction formwork machine

1. recycling material

2. Multiple extruder co-extrusion

3. Multiple layer formwork

PE, PP plastic building templates/formwork extrusion line:

It is made of PE, fly ash, calcium carbonate and other fillers which can replace steel templates and bamboo plastic sheet templates. Its advantages are as follows: low cost, light weight, continuous use 15 -30 times, Waste material can re-use.

PE plastic building templates extrusion line is consist of single screw plastic extruder, vacuum automatic feeding machine, sheet extrusion mould, 3 roller calibrating machine, cooling unit, haul off and cutting unit. With the characteristics of compact structure, superior performance, Screw deals with tube optimized design and use of high-performance alloy 38CrMoAiA professional processing which ensure that the plastic unit features homogeneous and stable extrusion, high yield, long life and other advantages. The barrel is made of casting aluminum tube heater heating, cooling wind, precise electronic temperature control instrument. We can adjust the shaping embossing device to make the sheet shaping well. Cutting part adopts fixed length device to ensure the precise length of sheet.

With our machine, you can produce 5 layers formwork board, outside two layers are PP or PE, using the recycling material, such as the recycled film, package, the reclaimed plastic pipe, barrel and other things!

In the middle it is made by the fly ash, calcium carbonate and the other fillers.

And there are two layer fiber glasses net in it! It made the board have the high intensity, small distortion degree and small expansion coefficient.

The plastic building templates can replace steel templates and bamboo plastic sheet templates. Its advantages are as follows: low cost, light weight, it can continuous use 20 -50 times, Waste material can be re-used to do new building templates!

We can design the machine according to your required size of formwork.

It is made of PE, fly ash, calcium carbonate and other fillers which can replace steel templates and bamboo plastic sheet templates. Its advantages are as follows: low cost, light weight, continuous use 15 -30 times, Waste material can re-use.

PE plastic building templates extrusion line is consist of single screw plastic extruder, vacuum automatic feeding machine, sheet extrusion mould, 3 roller calibrating machine, cooling unit, haul off and cutting unit. With the characteristics of compact structure, superior performance, Screw deals with tube optimized design and use of high-performance alloy 38CrMoAiA professional processing which ensure that the plastic unit features homogeneous and stable extrusion, high yield, long life and other advantages. The barrel is made of casting aluminum tube heater heating, cooling wind, precise electronic temperature control instrument. We can adjust the shaping embossing device to make the sheet shaping well. Cutting part adopts fixed length device to ensure the precise length of sheet.

With our machine, you can produce 5 layers formwork board, outside two layers are PP or PE, using the recycling material, such as the recycled film, package, the reclaimed plastic pipe, barrel and other things!

In the middle it is made by the fly ash, calcium carbonate and the other fillers.

And there are two layer fiber glasses net in it! It made the board have the high intensity, small distortion degree and small expansion coefficient.

The plastic building templates can replace steel templates and bamboo plastic sheet templates. Its advantages are as follows: low cost, light weight, it can continuous use 20 -50 times, Waste material can be re-used to do new building templates!

We can design the machine according to your required size of formwork.

Didn't find what you're looking for?

Post Buying Lead or contact

HiSupplier Customer Service Center

for help!

Related Search

Construction Formwork Panels

Metal Building Construction

Construction Building Decoration

Building Construction Water

Construction Machine

Machine Building

More>>