|

QINGDAO AORUI PLASTICS MACHINERY CO., LTD.

|

China plastic earthwork grid production line

| Payment Terms: | T/T,L/C |

| Place of Origin: | Shandong, China (Mainland) |

|

|

|

| Add to My Favorites | |

| HiSupplier Escrow |

Product Detail

Qingdao AORUI plastics machinery co.,ltd is specialized in plastic earth grid machine, and other plastic profile production line,board machine

1.Application

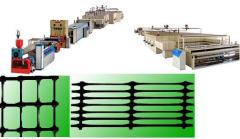

Fit for producing unilateral and bilateral plastic earthwork grid by making use of macromolecule polymer via extrusion, moulding, punching aperture, longitudinal and lateral draught. This kind of materials have high tensile strength and are widely used for foundation intensification, reinforcement of road surface and riverbank, as well as treatment of water and soil for permanent carrier, such as road, railroad, large airport, parking lot, dock and irrigation works to effectively prevent sedimentation, coast and landslide, prolong service life with wide market foreground.

Adopt advanced tensile technique and high precision control tech, environmental protection and energy-saving factors are considered completely, adopt clean energy, without gas, water and residue waste, reliable performance, stable quality, high efficiency, energy-saving performance, environmental protection, high automatization, etc.

2. Performance and Characteristics

Reasonable structure, high-tech, easy operation, high efficiency and low consumption

Extruder adopts PP, PE high-efficiency screw to assure high speed and high quality extrusion

Punching press adopts PLC control, easy operation, stable and reliable

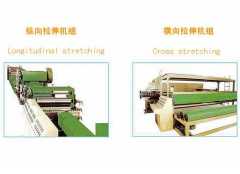

Unilateral tensile machine adopts multi-roller multi-grade tensile style to assure even tension and high intensity

Unilateral and bilateral heating system adopts oil conduction heating which can save energy and lower consumption

Electric system adopts frequency control technology, technical parameter is displayed digitally, high automatic control

(Friendly reminder: If you want to know more information and technology parameters, please contact with me directly!)

Fit for producing unilateral and bilateral plastic earthwork grid by making use of macromolecule polymer via extrusion, moulding, punching aperture, longitudinal and lateral draught. This kind of materials have high tensile strength and are widely used for foundation intensification, reinforcement of road surface and riverbank, as well as treatment of water and soil for permanent carrier, such as road, railroad, large airport, parking lot, dock and irrigation works to effectively prevent sedimentation, coast and landslide, prolong service life with wide market foreground.

Adopt advanced tensile technique and high precision control tech, environmental protection and energy-saving factors are considered completely, adopt clean energy, without gas, water and residue waste, reliable performance, stable quality, high efficiency, energy-saving performance, environmental protection, high automatization, etc.

2. Performance and Characteristics

Reasonable structure, high-tech, easy operation, high efficiency and low consumption

Extruder adopts PP, PE high-efficiency screw to assure high speed and high quality extrusion

Punching press adopts PLC control, easy operation, stable and reliable

Unilateral tensile machine adopts multi-roller multi-grade tensile style to assure even tension and high intensity

Unilateral and bilateral heating system adopts oil conduction heating which can save energy and lower consumption

Electric system adopts frequency control technology, technical parameter is displayed digitally, high automatic control

(Friendly reminder: If you want to know more information and technology parameters, please contact with me directly!)

Didn't find what you're looking for?

Post Buying Lead or contact

HiSupplier Customer Service Center

for help!

Related Search

Plastic Board Production Line

Plastic Pipe Production Line

Plastic Production Line

Plastic Profile Production Line

Plastic Plate Production Line

Plastic Sheet Production Line

More>>